Smart Routing: Engineering Clean Paths in Congested Fab Floors

- P3 Systems

- Jul 18, 2025

- 2 min read

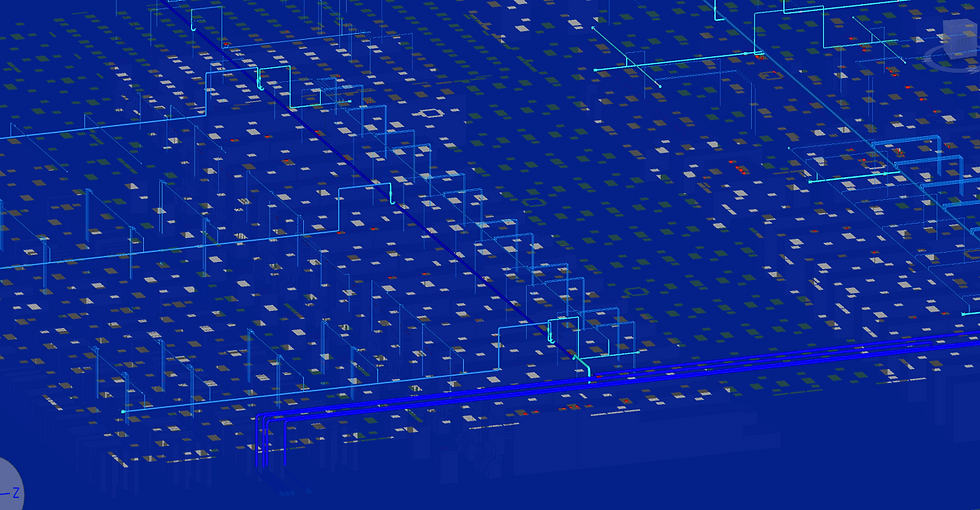

Routing piping in semiconductor fabs and PV module manufacturing plants is more than 3D coordination, it's a critical engineering discipline that affects uptime, tool access, contamination risk, and future expandability. The complexity of congested cleanroom environments demands intelligent layout decisions grounded in process logic, vertical zoning, and fabrication constraints.

What Makes Routing Smart in High-Purity Environments?

1. Functional Layout Driven by Process Flow

The best routing decisions begin with process understanding. Ultra-pure water (UPW), specialty chemical feed, chemical exhaust, and drain systems must be segregated clearly, both horizontally and vertically. Routing purely based on architectural convenience creates costly interferences and dangerous cross-contamination zones.

2. Respect for Cleanroom Zoning and Vertical Space

Allocation Fab floors are typically divided into vertical zones: gas lines at the top, chemical feeds and UPW in the mid-zone, and drainage systems at the bottom. Smart routing respects these zones and avoids unnecessary crossovers. Violations can lead to rework during QA/QC and disrupt HVAC or tool maintenance access.

3. Dead Leg Elimination for High-Purity Piping Systems

In UPW and chemical systems, dead legs are breeding grounds for microbial growth and contaminants. Smart layouts minimize dead legs by following DVS and ASME high-purity standards and maintaining consistent directional flow.

4. Tool Hook-Up and Maintenance Access

Routing must consider access for tool hook-up, sampling, pressure gauge reading, and valve operation. Valves buried behind ducting or placed above walkable ceiling height without service access are red flags.

5. Clash-Free Integration with Other Utilities

Smart routing involves early collaboration with HVAC, electrical, and instrumentation teams. Integrated 3D BIM coordination allows piping systems to be routed logically without last-minute site-level changes.

Smart routing isn’t just tidy drafting; it’s the backbone of functional cleanroom design. P³ Systems brings process insight, fabrication knowledge, and design foresight to every project, ensuring that your piping systems don’t just fit, they perform.

Planning your next high-purity piping project?

Comments